Laser Printer in Maharashtra, Free classifieds in Maharashtra | OLX

Laser Printer in Maharashtra, Free classifieds in Maharashtra | OLXFor a powder collection system to function properly, engineers must design and operate the system to maintain the (4) key parameters of air flow design (measured in CFM), air flow rate (measured in FPM), Static Pressure/Statistic Resistance and Air to Cloth Ratio (or A/C). Changes in any of these key system parameters will result in system-wide performance problems. The four parameters are fluid and directly affect others. Keeping everything at the right levels requires careful engineering, operation and maintenance. Let's go check these four parameters one by one. Air flow in CFM (Cottage per minute)CFM – What is it? – How much air the system moves is measured in cubic feet per minute or CFM. (Related terms include ACFM for actual cubic feet per minute and SCFM for standard cubic feet per minute). Most bags are sized and categorized according to CFM. In general, the greater the space that is sold or the greater the number of points collected in the most required system. The CFM generated by the system fan can be fixed or adjusted (Variable Frequency Drive or VFD Fans). However, the total CFM generated by a fan can affect changes in altitude, restrictions of ducts and size, as well as the flow resistance created by the system (work + filters). Why Important? – Without enough CFM the sources will not be properly ventilated. Bad ventilation directly causes damage to equipment, high emissions, loss of claimed products and dangerous environments (especially concern in facilities that handle fuel dust or hazardous materials). Under CFM can also negatively affect air speed, the relationship between air and fabric, and vacuum pressure, other key design parameters. Vacuum Pressure (Suction) " Static Pressure (Statistic Resistance)What are Static Pressure and Static Resistance? – Vacuum pressure or aspiration is measured in inches of water manometer, for example, and is the basis for a properly functioning dust collection system. The system fan should supply enough suction to remove the materials from the collection point (s) all the way through the duct to the baghouse and then through the filters and go out to exhaust. To do this you must overcome the resistance to the flow created by the filters and the duct. On the contrary, static pressure or static resistance is a resistance measure generated by the duct and filters in the baghouse. This is also measured in inches of water gauge. Why Important? – Without enough CFM the sources will not be properly ventilated. Bad ventilation directly causes damage to equipment, high emissions, loss of claimed products and dangerous environments (especially concern in facilities that handle fuel dust or hazardous materials). Under CFM can also negatively affect air speed, the relationship between air and fabric, and vacuum pressure, other key design parameters. Air speed and minimum transport speed What are the Air Speed and Minimum Conversation Speed? – The air speed within the system is measured in feet per minute, or ft/m. The system should be carefully designed to keep air speed within an acceptable range to prevent two important issues. The air speed is related to the MC as follows: ft/m = CFM ÷ transverse section of the duct (i.e., duct size). The dust accumulates inside the duct when the air speed is too low causing blockages and affecting the air flow and performance. Why Important? – High air speed can quickly use ductwork holes through abrasion (especially abrasive powders such as metals, ceramics, etc.) or can break delicately transported products such as processed (cereal), pharmaceutical, and others. Of greater concern is the low air speed, which can cause dust accumulation inside the duct and lead to poor dust capture in the inputs. For a powder trip suspended in the air it must most a or above the minimum transport speed for that product. If it falls below that minimum speed at any point in the duct, the dust will begin to settle or drop off from the airflow, which then accumulate in large piles that eventually drown from the duct. These dust accumulations within the duct create great security hazards. When combined with a source of ignition (such as a spark or a reservoir) they provide a large fuel for a fire or explosion of fuel dust, which can then be spread throughout the system, being continuously fed by dust accumulations below until reaching the dust collector. Additionally, these accumulations may eventually become so large that the duct collapses under the added weight. Need help designing your bag house? Are you looking for help in designing your dust collection system? We use our 40 years of experience to help you select the right system for your application. Air ratio to clothingWhat is the air of the powder collector to the proportion of the clothes? – The ratio of the gas volume (ACFM) to the total surface of fabric (sq. ft.) of the bag. First calculate the total fabric area of your collector by calculating the total filter area of each filter (bag diameter x 3.14 x length ÷ 144 [for the number of inches in a square foot] = filter cloth area) and then multiply that figure by the total number of bags in the collector. Take the CFM of the system and divide it by the total area of the filter cloth to get your air to cloth ratio. Why Important? – For the baghouse to capture the air current dust the unit must have a sufficient number of filters. By pushing more air through the same amount of filter material the efficiency of the low collection. Maintaining a proper relationship of air to fabric allows the baghouse to work with maximum efficiency, collecting more than 99.9% of all dust particles passing through it. For most applications, anything less than almost maximum efficiency will result in excessive emissions, violating pollution regulations and creating hazardous environments for workers and neighbors. Put all 4 variables together and design your system Now that we have discussed the 4 key design considerations, we will now see how to design a baghouse dust collection system to keep all 4 of these parameters within acceptable ranges to ensure proper functioning. Our next section is entitled: Design process for your Baghouse dust collection systemNext Section – Baghouse Design Guide OverviewDEAR SIR, I want to know how to take advantage of it (declared by ForMULA) TOTAL FILTRATION AREA & COMPRESSED AIR QUANTITY REQUIREMENT(FORMULA) I curiously explain everything in jail as I'm new to this project and I have to prepare a technical project for this. 1. TYPE OF FUEL- INDIAN COAL(GCV- 3000 to 5000 KCL/KG with 30-40% ASH CONTENT) 2.GAS FLOW VOLUME- 24480 CUBIC METER/HOUR 3. TEMPERATURE OF BOILER APTER APH- 180 DEGREE C 4. BOILER- 12 TPH(F limited 100) 5. DESIRED SPM- 50 Mg/CUBIC MTR 6. BAG FILTER INLET- FLY COAL ASH 7. ACR- 1.0 8. BAG- 160*4000 mmAyush In general, 3/4′ valves are good for up to 8 bags, 1-1/2′ valves are good for 8-14 valves... more than you need 2 "valves". Pingbacks & Pingbacks[...] continue from our last article where we review the 4 key design variables of air flow (in CFM), static pressure/resistance, [...] Next Section – Part 2 – The Four Key Baghouse System Design Variables [...]Leave a commentLeave a comment Your email address will not be published. Mandatory fields marked *Name * Email * Website Save my name, email and website in this browser for the next time you comment. Comment Notify me of follow-up comments by email. Notify me of new email messages. This site uses Akismet to reduce spam. .GET A QUOTECategoriesArchiveContact Us1930 Village Center Circle #3-5843 Las Vegas, NV 89134 Phone: (702) 848-3990 Explore our filtering solutions About Baghouse.comBaghouse.com is a leading manufacturer of dust collection systems for bags and equipment with more than 40 years of experience serving all industries.

Blouse Design - Latest unsupported blouse designs with matching blouse designLatest Backless Saree Blouseembroidery saree blouse design, new design bluuse 2019blouse design gallery for womenback neck designblouse neck designblouse neck designsbest designer sarees Blouse Design - Latest ideas by Saree BlouseBlouse Designs HD Gallerydesigner blouse gallery

Offset Printing Machine - Used Electronics & Appliances for sale in Pune | OLX

Offset in Gujarat, Free classifieds in Gujarat | OLX

Printing Machine - Hard Disks, Printers & Monitors for sale in Maharashtra | OLX

Offset Printing Machines in Pune, ऑफसेट प्रिंटिंग मशीन, पुणे, Maharashtra | Offset Printing Machines, Offset Printer Price in Pune

Offset Printing Machine - Used Electronics & Appliances for sale in Pune | OLX

Offset Printing Machines in Pune, ऑफसेट प्रिंटिंग मशीन, पुणे, Maharashtra | Offset Printing Machines, Offset Printer Price in Pune

Offset Machine - Hard Disks, Printers & Monitors for sale in India | OLX

Offset Printing Machine - Used Electronics & Appliances for sale in Pune | OLX

Printing Service in NIBM, Free classifieds in NIBM | OLX

Non Woven Bag Printing Machine Olx - DesaignHandbags

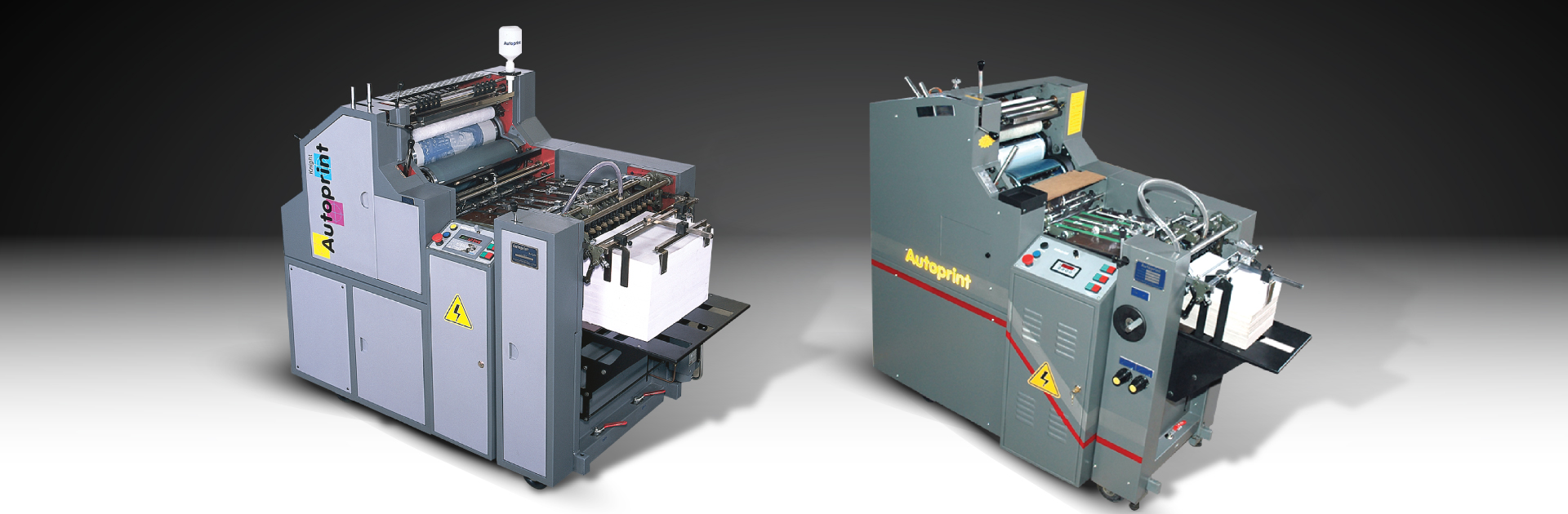

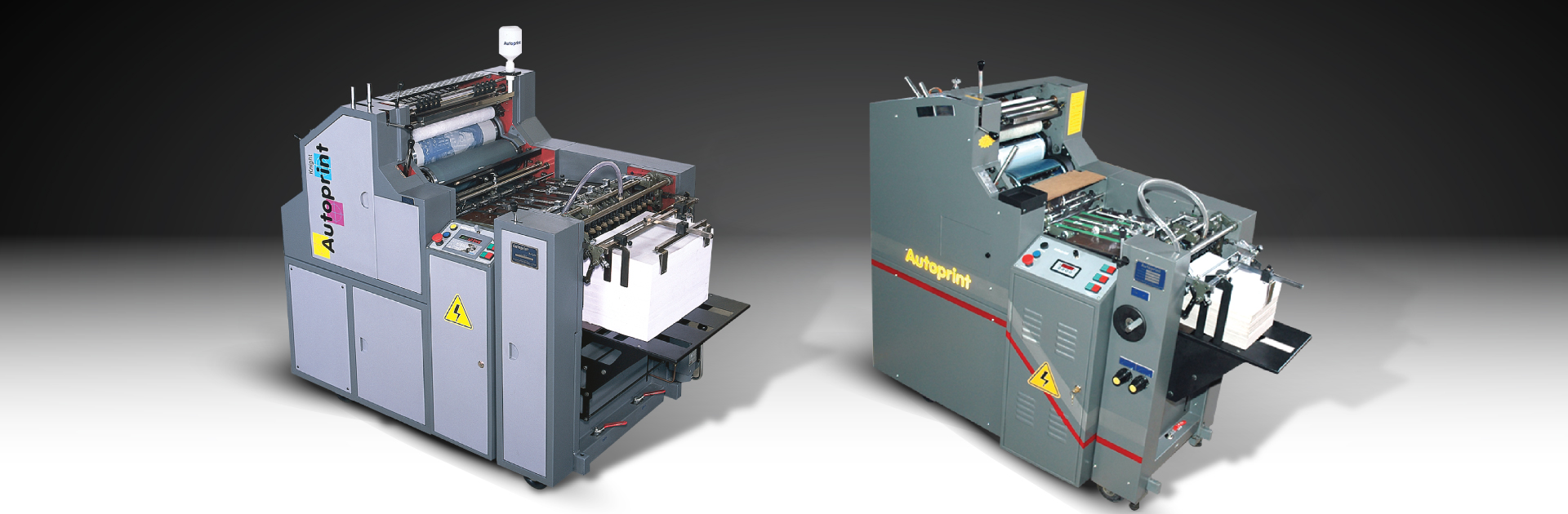

Offset Printing Machine Manufacturers | Autoprint Machinery

Offset Printing machine - Other Services - 1617167648

Non Woven Bag Printing Machine Olx - DesaignHandbags

Offset printing machine - Computers & Laptops - 1604808798

Offset Printing Machine - Hard Disks, Printers & Monitors - 1572205916

Offset Printing Machine - Used Electronics & Appliances for sale in Pune | OLX

Non Woven Bag Printing Machine Olx - DesaignHandbags

OFFSET PRINTING MACHINE for printing press - Computers & Laptops - 1608653922

Used Offset Printing Machine - Second Hand Offset Printing Machine Latest Price, Manufacturers & Suppliers

Non Woven Bag Printing Machine Olx - DesaignHandbags

Offset Machine Multigraph 1650 Size 13x17 Machine rupees 1,00,000/- - Other Services - 1572120988

Offset Printing Machine - Used Electronics & Appliances for sale in Pune | OLX

Offset printing machine..swift 150sx - Hard Disks, Printers & Monitors - 1606815848

Kitchens In in India, Free classifieds in India | OLX

Offset Printing Machine - Used Electronics & Appliances for sale in Pune | OLX

Offset Printing Machine - Used Electronics & Appliances for sale in Pune | OLX

Used Offset Printing Machine - Second Hand Offset Printing Machine Latest Price, Manufacturers & Suppliers

Printing Machine in West Bengal, Free classifieds in West Bengal | OLX

Printing Machines in Pune, Free classifieds in Pune | OLX

pad printing machine, date printer, logo marking system - YouTube

Imported Used Non Woven Bag Offset Printing Machines, Model/Type: 16x21, Rs 220000 /piece | ID: 17931081262

Offset Printing Machine - Used Electronics & Appliances for sale in Pune | OLX

Printing Machine in Pune, Free classifieds in Pune | OLX

Tube Printing Machine - Manufacturers & Suppliers, Dealers

Offset Machine in India, Free classifieds in India | OLX

Non Woven Bag Printing Machine Olx - DesaignHandbags

Offset Printing Machine - Used Electronics & Appliances for sale in Pune | OLX

For Sale Printing Machines Listings And Prices - Waa2

Non Woven Bag Printing Machine Olx - DesaignHandbags

Laser Printer in Maharashtra, Free classifieds in Maharashtra | OLX

Laser Printer in Maharashtra, Free classifieds in Maharashtra | OLX

Posting Komentar untuk "olx offset machine pune"